Handmade damascus kitchen knives, chef's knives and pettys gallery

Johan van Zanten makes two different types of kitchen knives; the chef's knife and the petty. The chef's knife is an all-rounder, most cutting tasks are performed with this knife during cooking. The petty is used when the chef's knife is too large or when you are working in the hand, for example when peeling an onion or preparing vegetables.

Both kitchen knives are characterized by their thin and easy cutting blade and comfortable handle. The chef's knife should be handled with the pinch grip, the petty has a longer and narrower handle so that it can be held with the entire hand.

Merovingian twist kitchen knife February 2021

Between the 5th and 8th centuries, the Merovingians were a dynasty of Frankish kings who ruled areas in and around the Netherlands. The smiths within this dynasty mastered the art of forging damascus steel and were known for their specific implementation of the twist damascus in which three extra thick layers were placed in the core of the inital damascus layer stack. By doing so, the pattern shows thick stars surrounded by smaller spherical layers. In the time of the Merovingian bladesmiths, twisting the damascus bars was also benefitial to strengthen the material.

This petty has 4 bars welded together resulting in a multibar construction. This knife wil be given as a gift; a piece of gas pipeline steel from the BalkanStream project has been forged into the upper bar at the spine of the blade. The pipeline steel shows as the brownish steel surrounding the lighter grey stars.

The wood for the handle is Coolibah burl, the pins and bolsters are brass.

Testimonial

Awaiting a response.

Stainless san mai kitchen knife November 2020

A lot of research and development went into the forging techniques for this stainless steel blade. While working stainless steel, the forging, polishing and heat treatments takes a lot more time and effort when compared to carbon steel. Fortunately the effort pays of; this knife has resulted in a completely maintence free kitchen knife.

The knife has a very unique combination of steels. The cutting edge is made of Elmax powder metallurgical stainless steel made in Sweden. This high-end material is known for its corrosion resistance and edge holding capabilites. The blade is a san mai construction, forged with Buderus Nitro-B and Bohler N690 damascus.

The dark blue handle is made from an artifical material named Juma Elforyn and looks like fish scales. The pins and bolsters are made from stainless steel.

Testimonial

Awaiting a response.

Handmade chef's knife March 2020

For the natural gas pipeline project TurkStream, this handmade knife was forged as a promotional gift. The knife is, among other tool steels, forged from a piece of steel from the gas pipeline.

The damascus pattern is a three-bar multibar, made up of twisted bars of explosion damascus. The dark gray star-shaped parts are the gas pipeline steel. In the bottom bar (at the cutting edge) the gas pipeline steel has been replaced by a 1.2442 tool steel, so that it is also hardenable and will cut well. This forging project was a collaboration between dutch bladesmith Maarten van Hattem and Johan van Zanten.

Testimonial

Awaiting a response.

Handmade kitchen knives February 2020

This is a set of kitchen knives consisting of a chef's knife and a smaller petty. They are both made from carbon steel random damascus. The bolsters and pins are made of stainless steel. Macassar Ebony is used for the handles. Both knives come in a leather sheath.

Testimonial

Awaiting a response.

Blue gyuto December 2019

For the natural gas pipeline project TurkStream, this handmade knife was forged as a promotional gift. The knife is, among other tool steels, forged from a piece of steel from the gas pipeline.

The damascus pattern is a three-bar multibar, made up of twisted bars of explosion damascus. The dark gray star-shaped parts are the gas pipeline steel. In the bottom bar (at the cutting edge) the gas pipeline steel has been replaced by a 1.2442 tool steel, so that it is also hardenable and will cut well. This forging project was a collaboration between dutch bladesmith Maarten van Hattem and Johan van Zanten.

Testimonial

Awaiting a response.

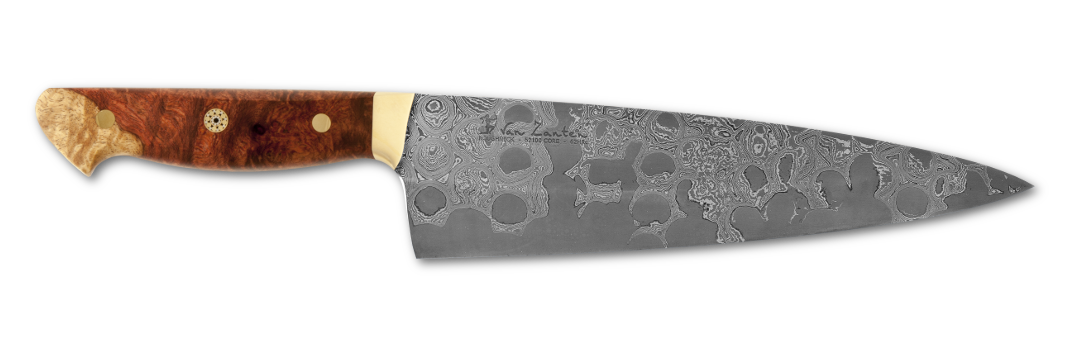

Unique damascus chef's knife September 2019

A unique chef's knife forged from bubble wrap damascus! When looking close, there's a lot going on in this pattern. The fun fact about this pattern is that it's almost impossible to remember how it looks, every time you pick it up you see something new. The handle is crafted from stabilized dyed poplar burl. The fittings are made of brass, the mosaic pin is brass and alpaca.

Testimonial

Awaiting a response.

Van Zanten 220s chef's knife with mammoth molar

A handmade kitchen knife with the handle of a mammoth's molar! In Northern Siberia ,mammoth molars and tusks are still occasionally found in the clay along the steep coastal walls. These fossils come from the mammoth that lived here about 15,000 years ago. Fortunately, the ivory can be used without having to worry; the mammoth became extinct a long time ago. The material has a beautiful look, feels pleasant and can be dyed in a special color.

The blade is forged from three-colored ladder damascus. The steels are 1.2842 - 1.2442 and 75Ni8. The hardness is +/- 61HRc. The grind is a two bevel hollow for good food release and ease of cutting. The thickness behind the cutting edge is 0,25mm (0,01").

Testimonial

" I found Johan after looking for an expert in Damascus steel. Inspired by the razor-sharp Japanese chef's knives, I wanted to have one made for my 40th birthday. What a professional! It has become a beautiful knife, a mammoth tooth was used for the handle, made green by a special process, the custom-made leather sheath completes the whole; really a piece unique! „

Forged san mai chef's knife January 2019

This chef's knife is a second attempt to forge a successful san mai construction. The san mai can be seen as a sandwich in which the blade of the chef's knife consists of 3 parts, a hard high carbon steel core with damascus steel forge welded on both sides. The core is made of 52100 tool steel, which is often used for rolling bearings in the industry and is very hard. It is also an excellent steel for use in the kitchen.

With very thin knives, it is difficult to keep the core in the center of the blade once it is stretched out during forging. For that reason I bought a rolling mill, it is now easier to keep the core centered. In this video you can see me working with the rolling mill!

There are 92 layers of bubble wrap damascus forge welded to the sides of the 52100 core.

The handle is made from a piece of yew from the customer's garden!

Testimonial

" Such a special experience. My family invited me to visit Van Zanten in Amersfoort. I was going to receive a nice birthday present.

In the cozy, traditional workshop we received an explanation about the manufacture of chef's knives. The forging of damascus steel, the grinding and the endless possibilities for the handle.

You can choose and consider, one example even more beautiful than the other. No, they are not yet ready; you have to wait for it. The knife will be made especially for you.

A unique tool. Your knife, just the way you want it. When it is finished you have a piece of art in your hands. And… a fantastic, razor-sharp, light and balanced tool. From now on you can choose recipes that require extra effort to cut! „

Peter

Chef's knives November 2017

For this damascus steel chef's knife I forged a san mai construction. You can think of it as a sandwich (3 layers). A hard steel with good cutting properties is placed in the middle. Decorative damascus is placed on both sides. The thinner the blade, the more difficult it is to keep the core steel centered. This can be seen in some places where the predominant core steel (dark gray) emerges. The result is an experimental bubble wrap san mai.

The core steel is forged from 52100 ball bearing steel. The hardness is +/- 62HRc.

The handle is made from Amboyna Burl, which also shows a piece of sapwood, the blonde piece on the back of the handle.

With this chef's knife I have moved the thickest point of the handle slightly forward so that the pinch grip offers a little more comfort. This is clearly visible in this HiRes photo.

Testimonial

" I am at home enjoying a piece of craftsmanship. I wish you many busy inspired days in your artistic forge. Hopefully many more beautiful works of art may come from your hands.

Do you know what I like about your work? With a Rembrand you can only look at it. With a Johan van Zanten you can grab it and hold it in your hands. Experiencing so much beauty takes your feeling to a more enjoyable dimension of cutting. Haha, just like the beautiful woman to whom I have pledged my heart, I have to treat the artwork with respect, otherwise she can bite quite a bit and make me bleed a lot. Go for it Johan. Cooking has remained my second love. „

Petty November 2017

The blade of this damascus petty was created by mixing several parts of previous forging projects together like a hodgepodge. After this, the piece was twisted. Here is an example video of the twisting of a damascus steel bar in the bladesmith workshop.

The handle is made from a disk of a mammoth tusk. This could be 15,000 years old! It feels very special to have something this old in your hands. In addition, it feels soft and it gives a good grip.

Random damascus knife May 2017

A playful and flowing damascus pattern is visible on the blade of this knife. It is forged from approximately 256 layers of tool steel. The handle is made of green stabilized Buckeye Burl.

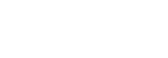

Chef's knife August 2016

Maple is the type of wood used to make the handle of this high-quality kitchen knife. The wood has been painted green through and through and has been half-quarter sawn, so that so-called mirrors can be observed in the wood when you move the handle in the light.

Three high-quality tool steels have been used for the damascus ladder pattern. The hardness of the chef's knife is 61 HRc.

Testimonial

" I've been the lucky owner of a Van Zanten chefs knife for a bit over a year now. It's a beautiful piece of craftmanship and is a joy to use daily. Super thin and sharp, it is very easy and light to use. The damast pattern and dark green maple handle are made/selected to order. So cool that you are working with knife that is unique, customised and that you actually know its origins. Before ordering the knife from Johan I had been on the lookout for a handmade chefs knife for a while. Finding out that there was a young knife-smith in the Netherlands making beautiful products triggered a visit to his workshop. Johan was happy to explain his process and philosophy, but what really got me was his craftmanship and the fact that he really puts in an enormous effort to create knives that are practical yet beautiful. In the case of damast knives, as the one I have, he controls every step in the manufacturing process, parts of which required him to develop his own machines and tools. You can specify (nearly) everything, so every knife he makes is truly unique. The knives may not be cheap, but in terms of value well worth it. Unique pieces of work that will grace your kitchen for your lifetime. „

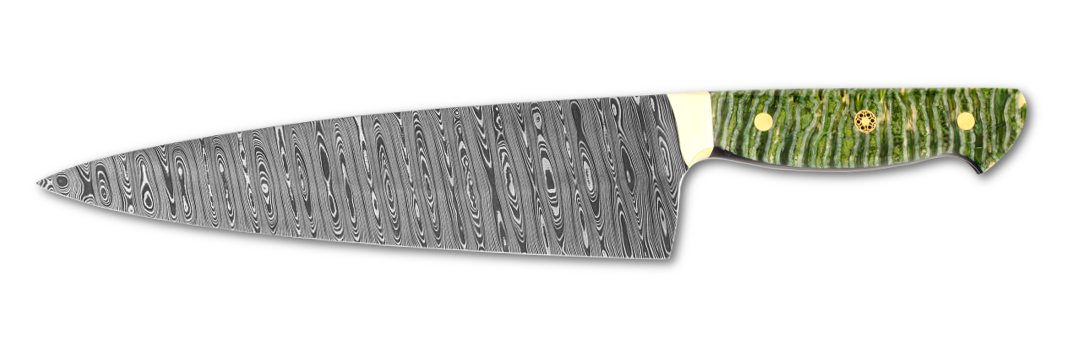

Chevron damascus western gyuto July 2016

For this high quality western gyuto I forged a chevron damascus pattern. Gyutos, originating from Japan, have very thin ground cutting geometries. It even makes cutting sweet potatoes and carrots easy.

The damascus of this gyuto is forged from three different high carbon steels. The tungsten in the steel contributes to a particularly high hardness of 61 HRc. The gyuto is very light and weighs only 190 grams. The balance point is right in front of the bolster.

Testimonial

" Hi Johan,

Thank you for forging and supplying this exclusive western gyuto.

It is a beautiful knife with a very nice "Random Chevron" pattern.

Since I consider your passion in combination with the refined technical operations as art, this knife will not be used as it is intended for.

For me this is "technical art" and it has gained a prominent place in my living room.

Thanks for forging and explaining the different treatments / techniques you use.

Kind regards,

Teun „

Elmax stainless PM steel petty September 2014

Here you see a small petty made from a piece of Elmax powder metallurgical stainless steel. The knife lies in the hand comfortably so an onion for example can be easily peeled.

The blade has undergone a long-term labor-intensive heat treatment including a -196 degree Celsius liquid nitrogen treatment, so it will remain sharp for a very long time. Behind the cutting edge, the blade is approximately 0.25mm thick.

Carbon steel damascus chef's knife February 2015

This carbon damascus chef's knife consists of 192 layers. The random damascus pattern is interrupted by very fine lines. When the chef's knife is moved in the light, these lines stand out even more and show a shimmering visual effect. This can be seen in the video.

The handle's blue maple has similar effect, there are so-called mirrors in this wood so that these stripes also jump as soon as you move the knife.

The chef's knife is hardened and tempered to 61HRc. The grind of this chef's knife is a "two bevel hollow". This means the blade is ground hollow in the upper and lower section of the blade. This results in very easy cutting and good food release.

Testimonial

" After I heard Johan talk about his work on Radio 1, I was captivated by the passion I heard. It needed only a visit to the blacksmith shop before I ordered a knife. A chef's knife although I am not a professional chef, just a hobby cook.

After we had chosen the materials and damascus pattern we liked, and after Johan had put a lot of work and -above all- craftsmanship into it, an end product arose that I am still very satisfied with to this day. A wonderful tool to work with in the kitchen and also a work of art to see. „

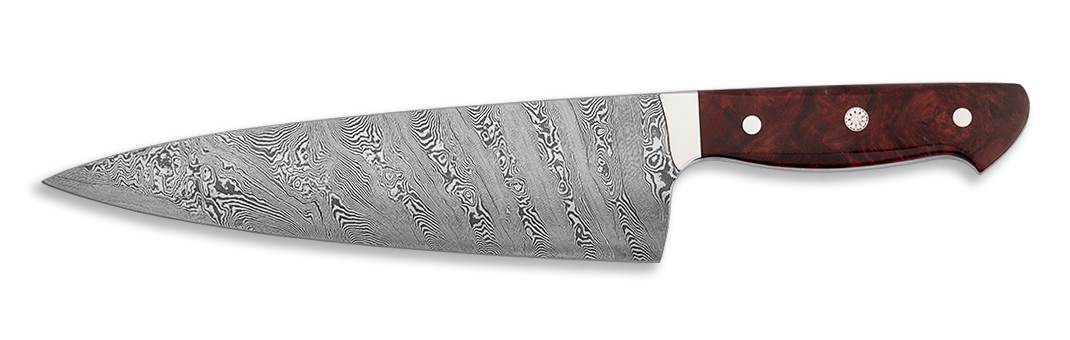

Twisted damascus chef's knife May 2015

This kitchen knife was forged by bladesmith Johan van Zanten in Amersfoort. For the blade, two types of tool steel were forge welded together, stretched out and folded in half. This process has been repeated 7 times to obtain 256 layers. After the folding, bar of steel was twisted to get a special pattern in the steel.

The handle is made of the exotic hardwood type "Jarrah". This piece of Jarrah has grown in a burl, giving the handle the special look and deep red color. The bolsters and pins are made of stainless steel.

Testimonial

" Johan, the knife is beautiful, my wife agrees as well. The nice thing is, when you cut cucumber into slices, the cut slice does indeed fall off the knife, with other knives you always have to give the slice a push. If I have understood correctly, this is due to the deeply etched damascus and the concave section in the blade, very clever and handy.

It is scary sharp, I noticed this especially when chopping parsley (chopping is not the right word, you make a rocking movement with the knife over the parsley).

If you give the knife a girl's name I would really like it if you name it after my wife Liesbeth.

Kind regards, Lucas „