Damascus

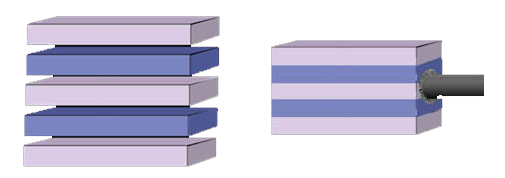

Damascus, also known as pattern welded steel, is a material which is made out of two different materials which are welded together. A pile is being made from alternately two types of tool steel.

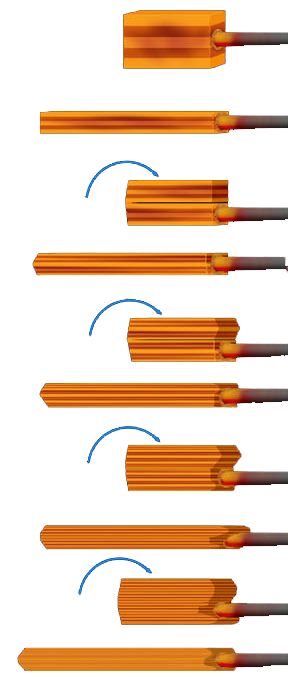

The bladesmith then keeps the steel into the fire until it gets white hot. During this process the temperature of the steel is just under melting point. This temperature makes the steel suited for welding under high pressure. The bladesmith takes the steel out of the fire, places the steel on the anvil and uses a hammer to weld the pieces together. The separate parts have become one massive clump. The blacksmith continues to extend the damascus to twice its length, cuts it in the middle and doubles up the damascus. The welding process is performed once more and now the layers have doubled (minus one). If, for instance, the blacksmith had begun his process with 8 layers the result after one doubling would be 15 unique layers.

This time consuming process is repeated until a given number of layers has been created. These layers can be seen at the surface of the knife and give the damascus knife its unique pattern.

Damascus which is meant for chef knives is usually made by two different kinds of tool steel. Tool steel is iron with a high percentage of carbon. The large amounts of carbon and other alloying elements give the steel the magnificent cutting capability.

The main reason for forging damascus is the esthetic aspect. The chef's knife becomes very appealing; every piece of damascus is unique.

In olden days Japanese bladesmiths would use the same techniques to forge samurai swords. Forging damascus had another purpose back then. The invention of blast furnaces had not yet been made and iron was extracted from iron smelting furnaces. The coarse material that was extracted from the low ovens, tamahagane, could not be used straight away. The material had to be given a more homogeneous structure. The tamahagane was being stretched and folded; we use the same technique today to get damascus. The old blacksmiths used to repeat the process more often than is being done today, up to 13 times, in this manner up to 60.000 layers could be created, to obtain an almost homogeneous material.

The steels used today to make damascus are almost perfect the way they are. The trick is to perform the right heat treatments; this will put the atoms in the ideal position in the crystal lattice. If performed right this creates a very hard and tough material.

The two different types of steel have different mechanical properties. This means that the materials wear in different ways, this causes the blade to serrate in the cutting edge which is useful when using the knife for certain cutting tasks.